|

Hardness Testing Machine | | | | | | | | | SAROJ make Brinell Hardness Testing Machine | | | Universal Testing Machine | | | | | | | | |

|

|

|

|

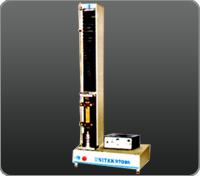

Model Unitek 9700 Series |

|

| |

|

|

|

|

FIE Universal Testing Series Unitek 9700 are microprocessor based Electromechanical machines with Servo drive designed for testing & Studying mechanical behavior of various materials like metals, polymers Etc. These machines offer good built-in features to offer excellent stand Alone performance for standard tests & great flexibility for complex Analysis. These machines confirm to IS, BS & ASTM standards.

|

| Main Features |

• Servo drive with lead screw gives an gives an advanced drive system with 1 to 1000 standard

speed range.

|

|

|

|

|

|

|

• Computerised Microprocessor based Instrumentation to measure display & store load & Displacement values.

• Provision for load cell interchangeability & thereby automatic selection of lad full scale.

• Speed selection through selector switch in steps or variable speed selector through

potentiometer.

• Facility for mounting different load cells & clamping devices to suit different tests & materials such as thin wires, metalsheets, fiberglass, leathers, springs, cardboards etc.

• Built in parallel interface to connect printer for data & curve print-out.

• Safety interlock for overhead & limit switch sensing to ensure protection test.

• Universal applications in R & D, education, quality control & production for test like tensile,

compression, bending etc. |

| |

Electronic Control Panel (Series TNE – 9700) :

The electronic control panel is built using 8085 microprocessor which incorporates sate of the art technology with following features.

• Front panel membrane type key board for test setup.

• 7 seg digital display of load & displacement / extension.

• Printer port for printer / plotter interface.

• Optional series port for communication with PC/AT etc.

• Optional add on facility for electronic extensometer.

• Storage on important parameters such as peak load, displacement at preload & maximum displacement after test.

• Selection of test type like tension, compression, or cyclic by key board.

• Preload selection (0.01 to 1 % )by thumbwheel to take care of initial slippage.

• Selection of stop or return crosshead after test. |

| |

| OPTIONAL ACCESSORIES : |

| |

FIE offers a wide range of optional accessories along with unitek 9700 Machines to cover almost

every material test requirement. .

Loaded Cells

FIE offers Strain gauges type Universal load cells in different capacities in the following nominal ranges:

100N, 250N, 1kN, 1.2kN. Load cells of different capacity can be offered as per customers requirements. |

| |

| Grip & Clamping Device |

| A wide range of grips are available from FIE such as : |

| |

• Vise type grips.

• Single thread grips.

• Compression Plates.

• Bending Fixtures.

• Shearing Attachments. |

| |

| Extenso meters : |

|

Electronic analog extensometers are offered along with interface card on the control panel to measure extension with a resolution of 1 micron.

• Model : EE-STRAIN GAUGE |

|

• SERIAL COMMUNICATION INTERFACE & SOFTWARE PACKAGE ON PC/AT

For complex test analysis the Unitek 9700 series machines can be offered with and optional serial port to establish communication with PC. The TNE – 9700 series control panel can be hooked to any PC/AT etc., using RS-232 communication port which is offered as optional. FIE offers different exhaustive application software package on PC to enable the user to effectively different parameters. |

|

The features include :

• User friendly main menu with popup/pulldown menus, prompt message & on line help.

• Extensive graphics on screen for curve plotting, magnification & zooming.

• Advanced fine handling for data save recall with database creation

• Printout option for Reports, Data, Graph etc. |

|

| The software package available are: |

|

1) Basic Evaluation 2) Exhausitive Evaluation 3) Rubber Textile 4) Compression shear & bending.

5) Spring Testing.

Statistical Evaluation software can be offered for all these program as optional. FIE also can provide custom built software solution to suit customer requirement. |

|

| SPECIFICATION : |

| |

| MODEL NO. |

UNITEK 9701 |

UNITEK 97025 |

UNITS |

| Load range |

0-1 |

0-2.5 |

kN |

| Load resolution |

1 st range:

0 - 40% of F.S. |

1 / 10000 of nominal load cell connected. |

1 / 10000 of nominal load cell connected. |

- |

2 st range:

0 - 100% of F.S. |

1 / 4000 of nominal load cell connected. |

1 / 4000 of nominal load cell connected. |

- |

| Load Measuring accuracy |

+/-1% from 2% to 100% of nominal load of loadcell used. |

+/-1% from 2% to 100% of nominal load of loadcell used. |

- |

| Max. Crosshead Stoke |

800 ( Without grips & load cell ) |

800 ( Without grips & load cell ) |

mm |

| Crosshead Displacement measurement |

0.1 |

0.1 |

mm |

| Crosshead speed range |

0.5-500 |

0.5-500 |

mm/min |

| power upply |

230 VAC, 50 Hz Single Phase |

230 VAC, 50 Hz Single Phase |

- |

|

| |

| SPECIAL OPTIONS |

| |

• Load full scale of 20,000 or 50,000 counts

• Crosshead displacement resolution of 0.01 mm. |

| |

| NOTE |

The power requirement of each model depends on the speed range and the capacity of the machine.

• Due to constant R & D Specifications & Features are subject to change without notice. |

| |