|

Hardness Testing Machine | | | | | | | | | SAROJ make Brinell Hardness Testing Machine | | | Universal Testing Machine | | | | | | | | |

|

|

|

|

|

Vickers Hardness Tester [Model VM-50] |

|

| |

|

|

|

| Built in projection screen to get accurate results. |

| Tests Loads - 5, 10, 20, 30 & 50 kgf. |

| Optional magnification - 70 X |

| Scale Least count 0.001 mm. |

| FEATURES : |

| Testing range is very wide, from soft metal such as lead, upto the hardest, like hardened

steel. |

| Same hardness number is obtained on the same specimen, regardless of the load applied. |

| The indentation is tiny and allows testing of aprecision finished part |

| Loading and unloading cycle is motorised. |

| Thin sheet metal is perfectly tested because the load applied is very small. |

| Built-in projection screen to get accurate results. |

|

|

|

|

| |

| 'FIE' Vickers Hardness Tester is a simple and accurate means to produce and measure the diamond indentation. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range from soft to hard and their accurate results are widely acclaimed. these strictly conform to IS : 1754 - 1968. |

| |

| TECHNICAL DATA : |

| |

Test loads |

- 5, 10, 20, 30, 50 kg |

Magnification of optical projection |

- 70 X |

Maximum test height (mm) |

- 200 |

Scale Least Count (mm) |

- 0.001 |

Throat Depth (mm) |

- 135 |

Machine dimension (mm) |

- L 585 x W 290 x H 860 |

Weight (approx) |

- 70 kg |

Power Supply |

- 220 VAC, 50Hz, 1-Phase |

|

|

| |

| CONSTRUCTION : |

| |

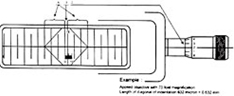

The robust machine frame is designed to accommodate the high precision loading system and an optical projection screen specimen is placed on a testing table. The test cycle is fully automatic the accurate load is applied on a diamond penetrator by means of a lever and weights. After a specific lapse of time the load is removed automatically. The objectives is indexed with the test piece and the diamond indentation is projected on the measuring screen the diagonals of the indentation can be measured by means of the micrometer screw of the projection screen.

|

| |

| STANDARD ACCESSORIES : |

|

| Standard Text Block |

- 1 Pc. |

| Diamond Penetrator |

- 1 Pc. |

| Weights |

- 1 Set |

| Flat anvil |

- 1 Pc. |

| Vee-Type anvil (small & Big) |

- 1 Pc. each |

| Spanners |

- 1 set |

| Electronic Cord |

- 1 Pc. |

| Instruction manual |

- 1 Book |

|

|

|

| |

|

|

|

|

Number of Special Accessories are available on request and as per special requirement |

|

|

|

|

|

|